Volkswagen has just three models to display in its Indian showrooms and among them is the Touareg. Indians just get a 6 cylinder 3.0-liter 225bhp oil burner with the options provided in countries abroad not available to us.

VW will offer the next generation of the Touareg with a gasoline hybrid version. First prototypes are already undergoing testing at various locales.

Power comes from a 333 hp supercharged (gasoline motor) 3.0-liter V6 with 440 Nm (325 lb-ft) of torque at just 3000 rpm. This engine is coupled to an electric motor that adds another 52 hp and 300 Nm (221-lb-ft) of torque. This E-motor gets its power from a 228-volt nickel metal-hydride battery pack.

Fuel economy in the gasoline hybrid fuel mode is just under 9 liters per 100 km (26 mpg) or 12 kmpl and it surely is an impressive achievement (a 20 % reduction) over the standard Touareg, but such savings do come at a hefty premium over the normal version considering the price of the hybrid kit costs a lot.

Hybrid systems as we all know, allows both gas and electric motor to work together to reduce fuel consumption and emissions. Speeds upto 50 km/h (30 mph) is taken care of by the electric motor alone while any more pace needed is supplied by the petrol motor.

For gas-free driving there will be a switch to use only electric mode. For more fuel savings the hybrid system uses stop-start system and regenerative braking to charge the nickel metal-hydride battery.

So has such technology taken a toll on performance? Read this - The Hybrid Touareg has not lost its power nor towing capabilities. VW quotes a 6.8 sec for the dash from 0-62 mph (0-100km/h) and that it can tow up to 3.5 metric tons.

Expect a very similar system with more power and torque to make it into the Porsche Panamera as well.

Press Release

BlueMotionTechnologies - Touareg V6 TSI Hybrid

* Prototype: Touareg Hybrid with new V6 TSI can tow 3.5 metric tons

* Charged V6 TSI and E-motor drive fuel consumption below 9 liters

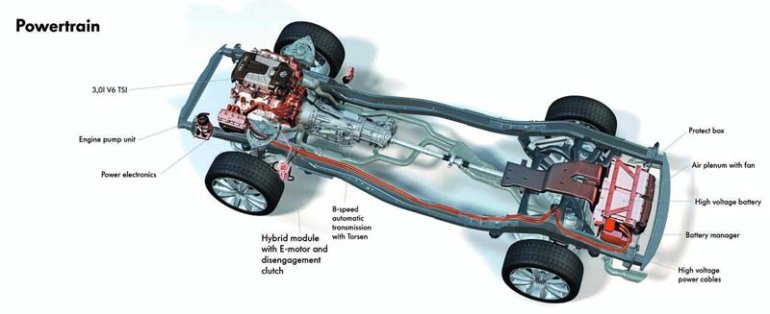

* Hybrid module was integrated between V6 TSI and 8-speed automatic

In parallel to pure gasoline and diesel versions, Volkswagen will be bringing the next version of the Touareg to market as a hybrid version too. Average fuel consumption: less than 9.0 liters fuel per 100 kilometers. CO2 emissions: less than 210 g/km. For the first time, there is now a near-production prototype that offers initial glimpses of the full hybrid technology that will be implemented on the future Touareg. This experimental platform has its conceptual basis in the current generation of the SUV. The car’s powertrain already embodies many aspects of the future Touareg Hybrid. It will be powered by a new V6 TSI - a highly advanced gasoline direct injection engine boosted by a mechanically-driven supercharger - in tandem with an electric motor. It will have a newly developed 8-speed automatic transmission. Volkswagen will be implementing a parallel hybrid drive on the future Touareg V6 TSI Hybrid. This version of the SUV will have a high-performance, full-time all-wheel drive too.

V6 TSI stands for maximum power with minimum consumption

The V6 TSI on the Touareg prototype is fun to drive and delivers 245 kW / 333 PS at 5,500 rpm. From its 2,995 cm3 displacement, it generates a maximum torque of 440 Newton-meters starting from 3,000 rpm. These characteristics match those of the Touareg with an eight cylinder engine, yet with the V6 TSI it is significantly more fuel efficient. This represents the principle of intelligent downsizing (less displacement plus gasoline direct injection plus inlet boosting) already established by Volkswagen on the globally successful TSI four cylinder engines, and it is now being applied to six-cylinder engines. The results are convincing. The substantial torque delivery that came from using a supercharger becomes even more fascinating with the addition of the E-motor, especially at low speeds. If required, an exceptional amount of torque is available from a standstill - a bonus that comes from a system that is designed for efficiency. To increase further this efficiency, the V6 TSI makes use of a switchable engine water pump. This remains off during the warm-up phase, ensuring rapid achievement of fuel efficient operation.. The pump is integrated into the vehicle’s overall heat management system.

V6 TSI plus E-motor drives fuel consumption below 9.0 liters

The E-motor integrated between the V6 TSI and the 8-speed automatic transmission adds power of 38 kW / 52 PS and up to 300 Newton-meters torque. In so-called boosting - where requests for maximum power and torque (by kickdown or gearshift selector in “S” position) are supported by the engagement of both V6 TSI and electric drive systems - the powertrain briefly supplies a power of 275 kW / 374 PS and the maximum available torque increases to 550 Newton-meters. In this case, the Touareg V6 TSI Hybrid prototype accelerates to 100 km/h in just 6.8 seconds.

The hybrid system of the Touareg was not designed to deliver sports car performance. Its purpose is to deliver very low emissions and fuel consumption values. It may therefore come as a surprise to learn that this exceptional performance is accompanied by an average fuel consumption of less than 9.0 liters per 100 kilometers. CO2 emissions are less than 210 g/km. The Touareg V6 TSI Hybrid will attain the limits of the Euro-5 and American ULEV2 emissions standards.

More than 25 percent better fuel economy

Compared to a conventional SUV of the same size, the hybrid concept yields fuel savings of more than 25 percent in city driving. Development engineers calculate an average savings of 17 percent in combined city, highway and freeway driving. Essentially, there are four parameters with which the Volkswagen prototype achieves this improved fuel economy.

Start-stop system: an integrated start-stop system significantly reduces fuel consumption, especially in urban driving.

Regenerative braking: during braking, the E-motor operates as a generator and recovers energy, which is then stored in the high voltage battery (NiMH batteries). This means that the E-motor recovers a proportion of the energy that would otherwise be rejected in the form of heat through the braking system. It comes into effect progressively during the initial travel of the brake pedal.

The E-motor: The vehicle can operate on the electric motor alone at speeds of up to 50 km/h, which reduces fuel consumption in city driving. In this case the V6 TSI is turned off, and it is disconnected from the transmission by a disengagement clutch. In this condition the Touareg V6 TSI Hybrid operates with zero emissions. Electric current flows from the battery to the E-motor via the power electronics which incorporates a pulse controlled inverter. On the later production version, there are also plans for a special E-switch that the driver can activate for pure electric driving.

Coasting: as soon as the driver removes his or her foot from the gas pedal, a clutch disengages the V6 TSI from the transmission. This is even possible at higher speeds - in the later production version up to about 160 km/h - and therefore in freeway driving as well. This eliminates mechanical drag losses, which in turn makes the Touareg coast significantly better. The driver can convert this directly into improved fuel economy by adopting an anticipatory driving style.

Intelligent energy mix

With regard to powertrain types - and their associated energy flows - besides electric driving and coasting there are two other operating modes: classic driving with internal combustion engine and the boosting that is typical of hybrid vehicles.

When driving with just the internal combustion engine, there are two possible modes of operation. In the first case, the Touareg is driven like a conventional vehicle with the E-motor performing the function of a conventional 12 V alternator, which it replaces, to supply sufficient energy for the vehicle’s electrical system and maintain battery charge (in this case a high voltage battery). In the second case, the engine supplies the energy needed to propel the vehicle plus the energy needed to charge the high voltage battery via the E-motor, but at a higher rate, replacing energy taken from battery when in conditions when the E-motor has been operating as an electric motor. This so-called load point shifting makes it possible to operate the engine at a more favorable level of efficiency in the engine load/speed map. The job of hybrid control is now to regulate this alternation of electric driving phases and active charge phases to achieve minimal fuel consumption.

Boosting: when the driver consciously activates a request for maximum power (kickdown or gearshift lever in “S” position), the E-motor supports the V6 TSI beyond the engine’s full-load curve. The powers and torques of these two motors are then transferred to the front and rear axles by the 8-speed automatic transmission. As previously mentioned, this briefly makes available a total combined power of up to 275 kW / 374 PS and a maximum torque of 550 Newton-meters.

In addition, since it can be controlled extremely quickly the E-motor is also used - in the framework of so-called transient compensation - to make positive and negative torque interventions. For example, when the driver makes a positive load request the E-motor briefly boosts the V6 TSI until it has reached its steady-state target value. This allows the Touareg Hybrid to keep accelerating. Negative torque interventions largely replace classic interventions via the internal combustion engine that are not optimal for efficiency, but are needed for occupant comfort during gear shifting or sudden charge changes.

The specific mode that is activated is shown by an energy flow indicator in the display of the RNS 510 radio-navigation system installed in the prototype vehicle.

Basic technical layout of the hybrid drive

Volkswagen has chosen a parallel hybrid drive for use in the Touareg. In contrast to other possible hybrid systems, both off-road properties and unlimited continuous climbing capabilities are assured. With a maximum trailer load of up to 3.5 metric tons, the Touareg V6 TSI Hybrid can also be recommended as an ideal towing vehicle. Furthermore, the parallel hybrid approach offers a higher level of efficiency than alterne hybrid concepts in cross-country and freeway driving.

The powertrain itself primarily consists of the V6 TSI, the 8-speed automatic transmission that is also ideally suited for hybrid and tow vehicle use and the hybrid module integrated between the internal combustion engine and the automatic transmission. The latter weighs 55 kilograms. The compact module houses - in one unit - the disengagement clutch located after the V6 engine and the E-motor.

The interplay of components is “directed” by a hybrid manager. This multi-functional unit is integrated in the engine controller and communicates via the CAN bus lines with units such as the automatic transmission, high voltage battery and so-called power electronics that controls the electric motor. The latter also manages the energy flow between the electric motor and battery. Using the DC/DC converter, the power electronics also ensures that the car’s 12V electrical system is supplied via the E-motor or the high voltage battery. Depending on the charge state of the battery (capacity: 6 Ah), vehicle speed and other vehicle-specific parameters, the hybrid manager automatically selects the ideal operating mode based on lightning fast analysis of all signals.

Nickel metal hydride battery in detail

The nickel metal-hydride battery used in the Touareg V6 TSI Hybrid reflects what is currently the best and most practical electric storage system for automobiles. Functional safety, robustness and cost are all factors that favor the high-performance NiMH battery.

The battery is located in a space saving area. On the prototype the cargo floor has been raised by 50 millimeters. The battery weighs 67 kilograms, consists of a total of 240 individual cells and therefore generates a voltage of 288 Volt. An additional duct integrated in the Touareg’s interior ventilation system and two separate fans are used to keep the battery within an optimal temperature range. A battery manager continually monitors battery charge by coordinating data with the hybrid manager integrated in the engine controller.

Special power cables connect the battery to the power electronics - located to the left of the engine in the front of the vehicle - to supply the E-motor with energy or - in the reverse case - to charge the battery by E-motor while it acts as a generator when braking (regenerative braking) or by the V6 TSI (via load point shift). In the event of a crash, the high voltage battery is protected by what is known as a “Protect Box”. The battery system, which includes the Protect Box, battery and ventilation components, weighs 79 kilograms.

Partial compensation for added weight of hybrid system

To compensate for a portion of the weight of the hybrid components (about 175 kilograms), the prototype exhibits numerous modifications compared to the production vehicle. One example is the full-time 4XMotion all-wheel drive. In today’s Touareg, the drive is transferred to the front and rear axles via a transfer box which contains a lockable central differential and a two-speed range gearbox. On the Touareg V6 TSI Hybrid this is replaced by a lighter Torsen differential similar to the one Audi uses on the Q7. All the traditional capabilities of the Touareg are fully preserved, such as its optimal properties as a towing vehicle.

Other changes compared to the production Touareg

Various components have been redeveloped to retain all the traditional convenience and safety-related functions of the standard Touareg in the Touareg V6 TSI Hybrid. For example, the prototype has electro-hydraulic power steering, which does not have to rely on a servo pump driven by the internal combustion engine. In addition, a high voltage air conditioning compressor guarantees comfortable interior temperatures on the Touareg V6 TSI Hybrid, even when the V6 engine is switched off. Instead of an alternator, the DC/DC converter integrated in the power electronics ensures a constant supply of power to the vehicle electrical system.

The 8-speed automatic transmission was also specifically tuned for hybrid use. Among other things, it received a special torque converter with larger lock-up system, an auxiliary electric oil pump (to maintain a supply of oil when the V6 TSI is switched off), a transmission heater to reach optimal operating temperature faster, and a modified transmission controller.

Car is started by electric motor

The E-motor now takes over the role of engine starter motor. This job is especially challenging, since restarting of the V6 TSI must be executed with a high degree of smoothness and precision to maintain comfortable transitions between the various modes of propulsion. As soon as the engine is to be restarted, the transmission’s lock-up torque converter is put in the “Slip” position and the E-motor’s speed is increased to a setpoint value prescribed by the transmission controller. Only then does the engine controller receive an enable to actuate the disengagement clutch. The E-motor “drags up” the V6 TSI by subsequent engagement of the clutch and, as soon as the cylinders fill, the engine is started by enabling of injection and ignition. The E-motor’s torque is increased by the amount of the momentary torque transferred by the disengagement clutch during the drag operation and - after the internal combustion engine has started - it is reduced again in response to the increase in engine torque. When positive engagement occurs at the disengagement clutch, the lock-up torque converter is engaged again. All of this sounds complicated, and it is complicated, but the system operates in such a way that the driver and occupants are completely unaware of its contribution to smooth progress. And that is just how things should be.

Source- Global Motors