Audi is stepping up its game by integrating artificial intelligence across its production and logistics operations to enhance efficiency, quality, and innovation. With over 100 AI projects in various stages, the brand is steadily bringing smarter tech into series production, focusing heavily on quality control and generative AI applications.

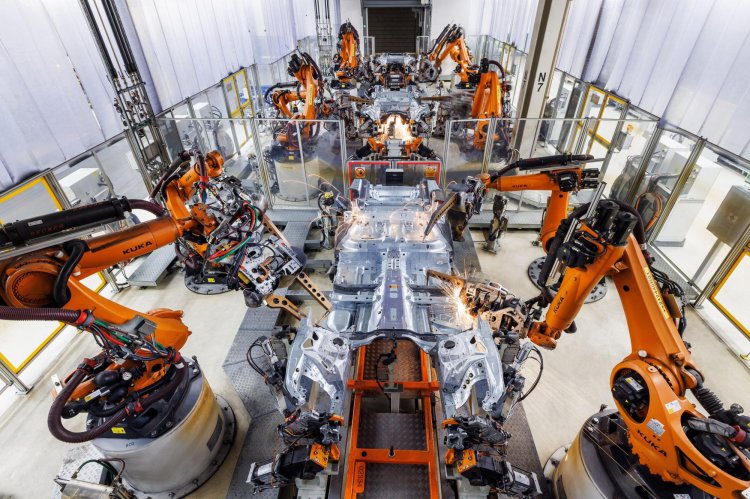

Among the key innovations is “Tender Toucan,” an AI tool that speeds up tender analysis by up to 30%, streamlining drivetrain and battery planning processes. Meanwhile, Audi’s “IRIS” system at Ingolstadt and Neckarsulm ensures accurate label placement using AI-driven image recognition, saving time and boosting accuracy. Another project, “Weld Splatter Detection” (WSD), developed with Siemens, uses AI to identify welding defects—enhancing quality and paving the way for robotic automation by 2025.

Also read: Olympic Champ Neeraj Chopra Becomes Audi India’s Newest Brand Face

Audi’s AI push is backed by its involvement with IPAI in Heilbronn, which is set to become Europe’s largest AI hub. With strong data infrastructure and real-world testing at its Böllinger Höfe site, Audi is charging ahead toward its vision of a fully connected, AI-driven 360factory.