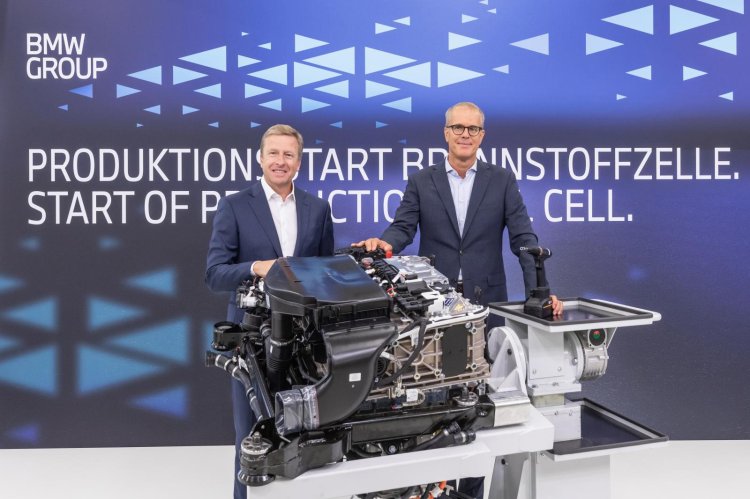

The BMW Group will now be manufacturing highly efficient fuel cell systems at its in-house competence centre for hydrogen. This technology is one of the core elements in the BMW iX5 Hydrogen and generates a high continuous output of 125 kW/170 hp. It teams up with an electric motor featuring fifth-generation BMW eDrive technology and a high-performance battery purpose developed for this vehicle to enable its powertrain to deliver 275 kW/374 hp.

The development team incorporated the powerful drive system – comprising two hydrogen tanks, the fuel cell and the electric motor – into the existing #BMW X5 platform for the small production run. The BMW iX5 Hydrogen already successfully demonstrated its excellent everyday usability, even at very low temperatures, during the final round of winter testing in Sweden at the start of this year.

The impressive testing results of this new small-scale series of cars are rooted in the BMW Group’s extensive experience with the use of hydrogen as a drive technology. Hydrogen-powered combustion engines had already been in use prior to the arrival of the fuel cell system. Efficiency considerations prompted the BMW Group to continue development work in this area from 2015 with the BMW 5 Series GT Hydrogen Cell based on fuel cell technology. Fuel cell technology has since been steadily refined by harnessing the company’s vast know-how in the field of conventional drive technologies and applying the exacting standards of all-round efficiency it expects of all its vehicles.

The BMW Group sources the individual fuel cells required for manufacturing the BMW iX5 Hydrogen from the Toyota Motor Corporation. The two companies have enjoyed a partnership characterised by trust for many years and have been collaborating on fuel cell drive systems since 2013. Fuel cell systems are manufactured in two main steps. The individual fuel cells are first assembled into a fuel cell stack. The next step involves fitting all the other components to produce a complete fuel cell system.